Project Review

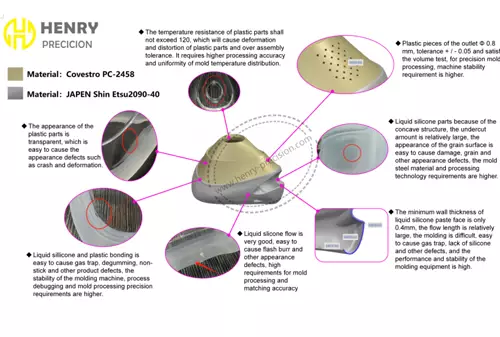

| Manufacturing process | Rapid prototype mold (referred to as sample mold) |

| Material | LSR |

| Insert Material | Steel S136 |

| Product size | 124x109x73mm |

| Mold size | Wx300 Lx300 H (mm) (Lung Kee standard mold holder: 3030) |

| Cavity | 1 |

| Delivery time | 10 days |

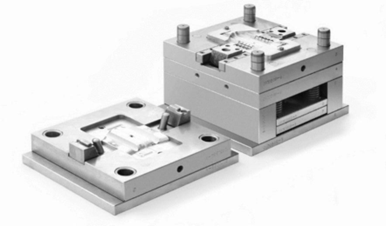

Henry Standard Mold Holder

Rapid prototype mold is a quick, economical option utilizing high-speed, high-precision machining, simple & reliable design solutions, and effective procedures. It’s produced in a short lead time, meeting part specifications for accuracy and quality.

For over ten years, HENRY’s technical team has focused on prototype mold R&D and production, summing up experience to create unique standards. This balances quality, speed, and cost, maximizing benefits for customers, minimizing costs, and achieving mutual success.

Henry standard mold frame:

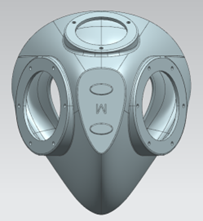

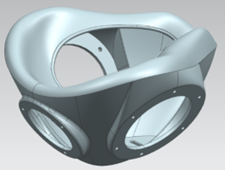

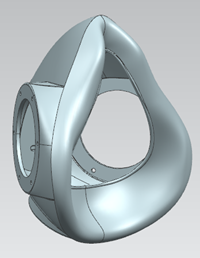

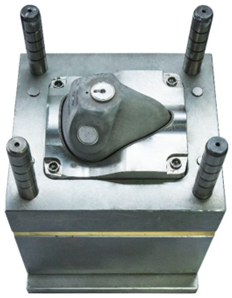

Henry Respiratory mask mold:

We utilize Henry Shared standard molds for this part, ensuring modularity & reusability, thereby reducing lead time & mold costs.

Conventional molds require die holders from suppliers with 3-10 days lead time and high costs. Rising steel prices have led to a 30% increase in mold prices in recent years.

Characteristics of rapid prototyping tools in Henry:

- Tooling components should be standardized, known to mold manufacturers. Traditional molds are custom, driving up costs. Henry has incorporated standard slides & lifters to reduce lead times & mold costs for customers.

- After understanding part specs and customer expectations on mold life & delivery, Henry’s tech team offers professional, economical solutions within 24 hours.

- During product development, engineering changes after sampling are unavoidable due to prototype tooling needs. Henry’s prototype tooling is adaptable, but customer charges may apply for customer-requested changes.

- Henry’s prototype tooling life spans 500-50,000 die runs, depending on P20 or NAK80 steel. We’ll confirm the most suitable quote with the customer at quotation time.

- Lead time for prototype molds is 1-2 weeks, longer for complex or large sizes, but not exceeding 4 weeks.

- Proto molds use shared holders (not priced in mold cost), owned by Henry. Cavities, cores, slides, lifters are customer-owned after payment. Disassembly requests incur extra fees for mold carrier & shared parts.

- Henry offers free storage for prototype tooling for 2 years. After 2 years without orders, tooling will be scrapped upon customer confirmation, or customer agrees to pay repair & storage costs.

- Rapid prototype molds come with a DFM report detailing parting lines, gate locations, ejector positions, drafts, wall thicknesses, and tolerances for customer confirmation before high-volume production, reducing defect risks.

If you have any new project, please contact us now for a free quote!