LSR is preferred for automotive products due to its lack of TPEs and natural rubber drawbacks like limited temp range, fragile lifespan, and poor flow. Silicone resins operate up to 250°C (480°F) and maintain performance in subzero temps. Unlike others, silicone does not brittle or degrade over time or cycling.

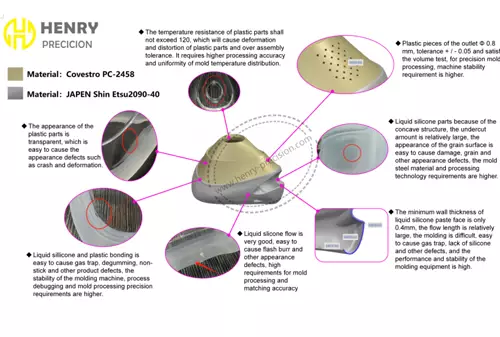

LSR’s low viscosity allows easier mold flow and consistent thickness. Available in durometers 30-50 Shore a, LSR offers design flexibility for complex geometries and thin thicknesses. For instance, a 50 mm silicone diaphragm can be 0.1 mm thick with a 0.02 mm tolerance.

To discuss your automotive products, contact the experts at Henry.

With more than 10 years of knowledge and experience in LSR, LSR overmolding, and LSR multipoint injection molding, we are able to provide superior solutions for our customers.