Why Henry Precision is Your Trusted Silicone Molding Partner

At Henry Precision, we specialize in providing high-quality silicone molding solutions to meet the diverse needs of our clients. As a silicone molding manufacturer, we

At Henry Precision, we specialize in providing high-quality silicone molding solutions to meet the diverse needs of our clients. As a silicone molding manufacturer, we

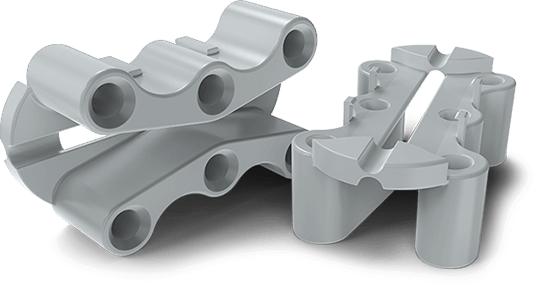

At Henry Precision, we specialize in providing high-quality silicone molding solutions to meet the diverse needs of our clients. As a silicone molding manufacturer, we focus on delivering customized solutions for industries ranging from medical devices to consumer electronics. Our dedication to innovation and quality has earned us certifications like ISO 9001 and ISO 13485, ensuring that every product we manufacture meets rigorous standards. Comprehensive Silicone Molding Solutions Henry Precision‘s facility is equipped with state-of-the-art technology, including over 60 LSR machines and a 5,000 square meter Class 100K cleanroom. This allows us to offer a wide range of silicone rubber

At Henry Precision, we are constantly pushing the boundaries of what is possible in silicone molding. As a trusted silicone molding manufacturer, we combine extensive experience with cutting-edge technology to provide innovative solutions for the medical, automotive, and consumer electronics industries. We specialize in LSR injection molding and precision plastic injection molding, offering a wide range of services tailored to meet your specific requirements. Our commitment to quality, precision, and customer satisfaction ensures that every product we create exceeds industry standards and meets the highest expectations. Advanced Technology to Achieve Superior Product Quality Our commitment to technological excellence is demonstrated

Client Overview: Our client, a leading consumer electronics brand, required a rapid solution for the prototyping of a new product series. The challenge was to

📌 Project Overview Industry: Daily Consumer GoodsApplication: Leak-proof portable water cupMaterial: Tritan™ Copolyester (BPA-free)Process: High-precision injection molding + ultrasonic welding 🔍 Project Background The client,

Analysis of Post-Processing Techniques for Plastic and Silicone In industrial manufacturing, post-processing techniques for plastic and silicone play a crucial role in enhancing product appearance,

2# Factory Building, East Factory Area, Jianlun Industrial Park, Dache Industrial Zone, Nanlang Town, Zhongshan City, China