Advantages of Silicone for Audio Products

Silicone is strong, flexible, and soft. It makes audio products last longer, sounds better, and stay safe from dust and water. With over 13 years of experience, we use advanced LSR manufacturing technologies to create audio parts tailored to customers’ needs. Contact us today!

liquid silicone Rubber applicable to the electronics Product.

Sound Sealing Components

Buttons and Operator Interface

Anti-slip and cushioning stripslicone

High and low temperature resistant liquid silicone

Antistatic liquid silicone

Industry Solutions

Henry Precision provides tailored LSR solutions for audio products

For components that enhance sound quality, device control, and user interaction, we manufacture sound sealing components, such as silicone rubber sleeves, and buttons and operator interfaces to improve audio performance, prevent sound leakage, and enhance user comfort.

For the protection of audio devices, we supply anti-slip silicone strips and cushioning strips to safeguard devices from impact and vibration, extending their service life.

Henry Precision offers custom liquid silicone solutions with waterproof, dustproof, thermal conductive, and shock-resistant properties, developed by our professional R&D team. Combined with our molding capabilities, including LSR injection molding, over-molding, post-processing technologies, etc., we can deliver high-precision products for our partners.

We also offer OEM/ODM services, offering one-stop services from design and manufacturing to assembly, simplifying production processes and reducing time and costs for customers.

Efficient Production

Advanced LSR manufacturing technology ensures high-speed LSR injection molding, reducing lead times and boosting production efficiency.

Quality Assurance

Strict quality control systems guarantee consistent product performance, meeting stringent standards for audio product components and applications.

Continuous Innovation

Dedicated R&D team drives material and process advancements, delivering cutting-edge solutions tailored to evolving demands of audio products.

LSR Material Applications in Audio Products

Liquid silicone benefits audio products with durability, flexibility, and precision. Click here to learn more about silicone components for audio products.

Bluetooth speaker

Silicone case for Bluetooth speaker boasts a smooth, comfortable surface, enhancing the speaker’s premium feel. Its seamless, bubble-free encapsulation significantly improves aesthetics and sealing.

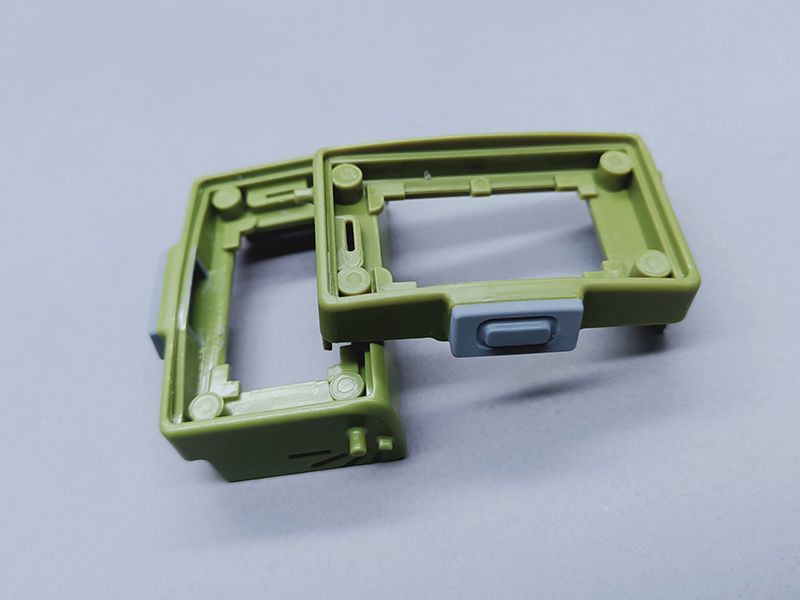

Buttons and Operator Interface

The silicone keys for the function bar of the audio provide good tactility and force feedback, as well as waterproof and wear-resistant properties. The characters on the silicone buttons are made by relevant processes, which are clear and durable.

Earphones

For in-ear headphones, custom silicone sleeves fit tightly and make the sound better. They are soft, comfy, and safe to wear for a long time. As a silicone ear plug manufacturer, we ensure durability and precision in every product.

Audio Seals

The silicone anti-leakage ring for audio devices stops sound from leaking. It makes sound clearer, better, and more focused, creating an improved, enjoyable, and high-quality listening experience for everyone.

Custom Silicone Ear Plugs and Other Silicone Audio Products FAQs

Liquid silicone offers durability, flexibility, and precision in audio products. It improves sound quality through effective sealing, enhances user comfort with soft ear tips, and protects components from dust, moisture, and vibrations, ensuring reliable performance and longer product life.

Yes, we specialize in bulk production, offering high-quality liquid silicone rubber products to meet large-scale requirements. Except for ear tips, we also provide other silicone components for audio products. If you’re interested, contact usnow!

Yes! Send us your drawings and we will provide accurate quotations within 24 hours.. For more questions about order, you can go to FAQs or directly CONTACT US to get detailed consultation. We are happy to serve you anytime!

Our expertise in silicone ear plug supplies and silicone sleeve manufacturing ensures exceptional comfort, durability, and precise fit. We also provide custom molded silicone ear plugs that enhance audio quality, user comfort, and product reliability.

Yes. We currently offers 3D modeling, custom mold drawing, plastic & silicone production, surface treatment, and comprehensive after-sales service. With more than 13 years of manufacturing experience, we have helped more than 1,000 customers achieve success globally. Offering competitive prices without compromising product quality, Henry Precision is your trusted partner in silicone manufacturing.

Let’s build the future with innovation.

Please provide the following details to help us better understand your needs and get in touch with you as soon as possible.

You can send us 3D drawings in STL, STEP, IGES and 2D drawings in PDF. We will provide accurate quotations within 24 hours.

From concept to completion, we provide a one-stop silicone mold manufacturing service.