Medical & Life Science Injection Molding | ISO 13485 Certified

Reliable LSR & Plastic Injection Molding for Medical Applications

Henry Precision has been a trusted manufacturing partner since 2011, specializing in liquid silicone rubber (LSR) and plastic injection molding for the medical, healthcare, and life sciences industries. With our ISO 13485-certified facility and controlled cleanroom environment, we deliver high-precision, biocompatible medical components that meet strict industry regulations.

From respiratory devices to fluid management components, we provide customized solutions for critical healthcare applications, ensuring safety, durability, and precision.

Benefits of Medical-Grade LSR

High Biocompatibility

Ideal for applications requiring direct contact with human tissue, such as implants and surgical devices, LSR is non-toxic and hypoallergenic.Chemical & Physical Stability

Medical-grade LSR resists harsh chemicals, high temperatures, and UV exposure, ensuring long-term durability in demanding environments.Elasticity & Flexibility

The excellent elasticity and flexibility of LSR allow for high-performance medical components that can stretch, compress, and return to shape without losing integrity.Transparency

High transparency LSR is perfect for components that require visibility, such as sensor housings or transparent seals, ensuring better functionality and monitoring.Sterilization Resistance

LSR’s ability to withstand high-temperature sterilization processes, like autoclaving, makes it a reliable choice for medical devices that require sterilization.

Why Choose Henry Precision for Medical Molding?

Ensuring compliance with medical-grade manufacturing standards.

Over a decade of experience producing precision healthcare components.

Safe for medical, surgical, and life science applications.

Minimizing contamination risks for critical medical devices.

Supporting complex multi-material and multi-component designs.

From prototype to mass production, ensuring efficiency and cost-effectiveness.

Medical & Life Science Applications

We manufacture a wide range of medical-grade silicone and plastic components, including:

- Respiratory Devices – Silicone seals, masks, and valves.

- Fluid Management Components – Tubing connectors, gaskets, and seals.

- Syringe & Drug Delivery Parts – Stoppers, plungers, and soft-touch components.

- Multi-Material & Overmolded Parts – Plastic-LSR, metal-LSR integration.

- Surgical & Diagnostic Equipment Components – Custom precision parts for medical instruments.

Examples of LSR materials used in medical device products

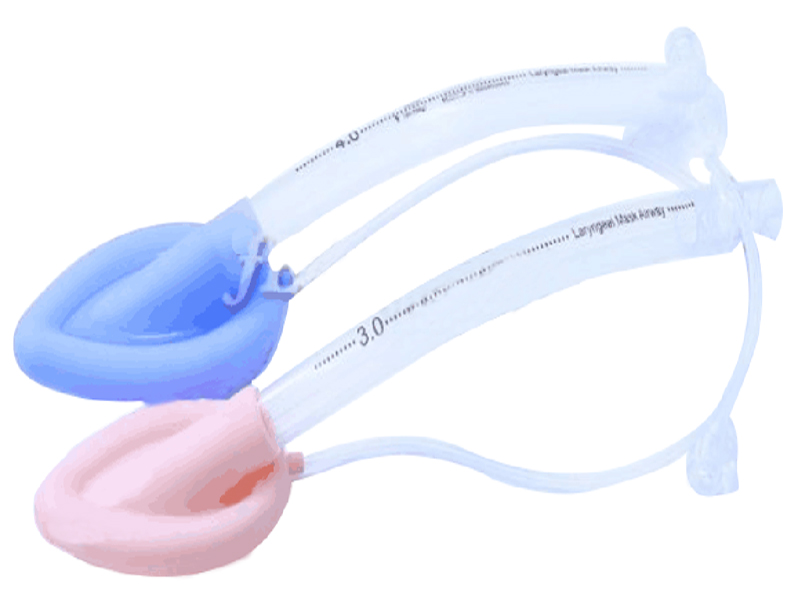

respirator mask

Made from biocompatible LSR, offering excellent flexibility, temperature resistance, and durability against impacts, ensuring comfort and long-term wearability.

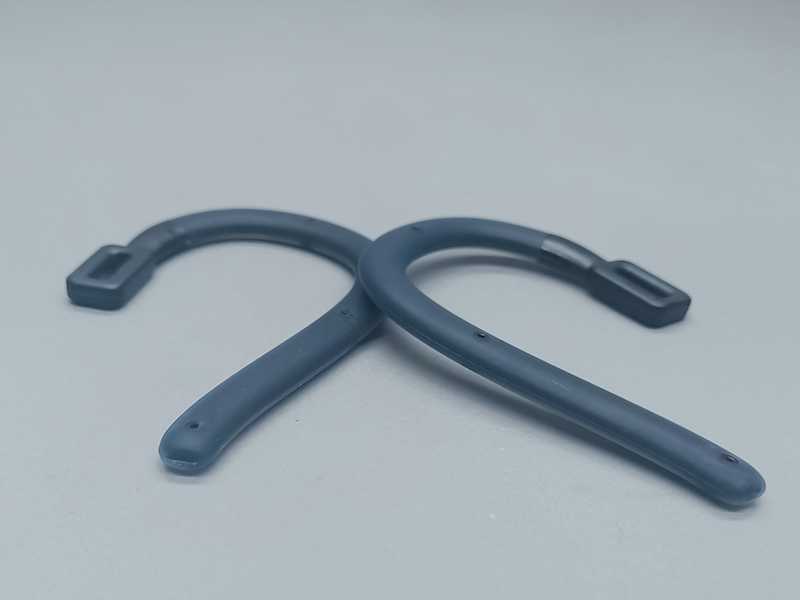

nasal mask

LSR material provides a soft, hypoallergenic fit with high durability, slip resistance, and stability under varying temperatures.

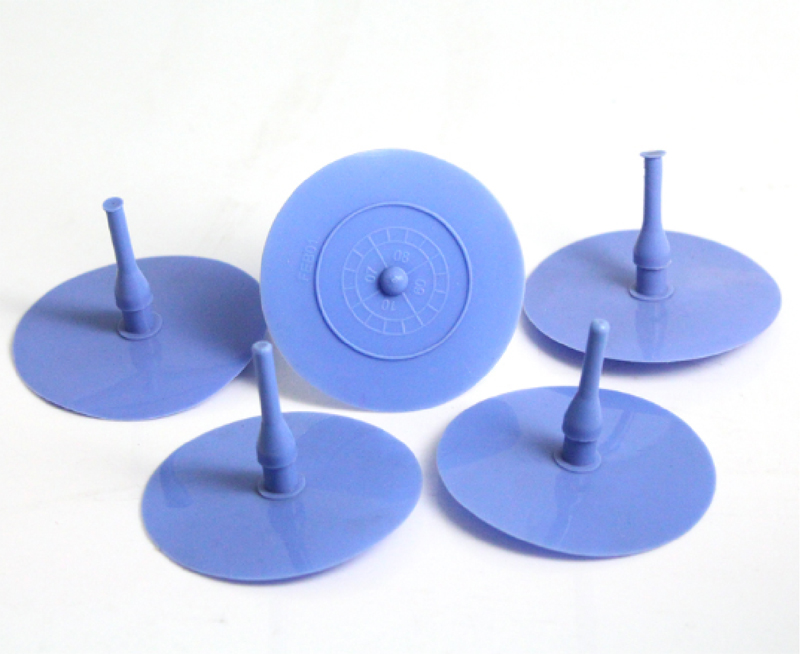

Anti Teeth Grinding Teether

Crafted from flexible, non-toxic LSR, ensuring comfort, impact resistance, and reliable performance in different temperature conditions.

nasopharyngeal mask

Made from biocompatible and flexible LSR, providing comfort, secure fit, and resilience under diverse environmental conditions.

Our Commitment to Quality & Compliance

At Henry Precision, we adhere to strict medical manufacturing standards, ensuring every component meets regulatory and performance requirements. With our automated production, rigorous quality checks, and in-house testing, we guarantee consistent, high-quality output for your medical device needs.

📩 Contact Us Today to discuss your project and get a customized quote!

Let’s build the future with innovation.

Please provide the following details to help us better understand your needs and get in touch with you as soon as possible.

You can send us 3D drawings in STL, STEP, IGES and 2D drawings in PDF. We will provide accurate quotations within 24 hours.

From concept to completion, we provide a one-stop silicone mold manufacturing service.

-拷贝-副本-拷贝.jpg)

-拷贝-副本-拷贝.jpg)

-拷贝-副本-拷贝.jpg)