Silicone for Automotive Excellence

Henry Precision drives innovation in automotive silicone manufacturing since its foundation. Our LSR car parts enhance autonomous vehicles through advanced engineering. Vehicle silicone sealant supplies from our production lines power modern automotive performance through:

- Chemical-proof durability

- Advanced noise dampening

- Ultra-lightweight design

- Precision sealing technology

Next-Generation LSR Parts for New-Energy Automobiles

Transform new-energy vehicles with our silicone for cars applications

Automobile engine component sealing

electrical system insulation

brake system sealing

air conditioning system sealing and vibration damping

automotive interior components

Antistatic liquid silicone

Industry Solutions

We deliver the following silicone for vehicles manufacturing solutions.

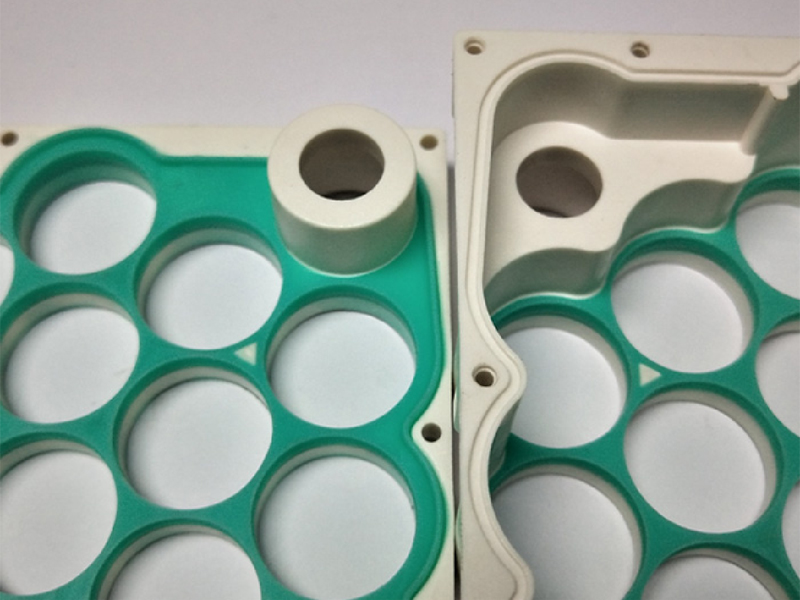

Engineered LSR components for autonomous vehicles ensure precise fitting for automotive parts, effectively meeting sealing demands.

Automotive silicone components feature tailored durometer ratings for optimal noise reduction. Our silicone for vehicles manufacturing process ensures consistent performance under extreme conditions.

Liquid silicone coatings protect auto components from oil, acid, alkali, and chemicals, extending part lifespan.

From design to raw materials, mold creation, manufacturing, process optimization, quality control, and logistics, we deliver seamless technical services. Our vehicle silicone sealant supplies undergo rigorous testing to meet automotive industry standards.

Efficient Production

Rapid tooling and mass production of car components made of LSR meets urgent industry demands.

Strict Quality Assurance

Henry Precision conducts strict testing & QC from raw material procurement to shipment, ensuring products meet industry high standards.

Future-Ready Innovation

Pioneering silicone automotive solutions on both silicone materials and technologies are developed to support the evolving needs of new energy vehicles.

Innovation in Motion - LSR car parts for autonomous vehicles

LSR materials are widely applied in new energy vehicle parts, improving product performance, quality, and enhancing user experience. Contact us to get the latest quotation.

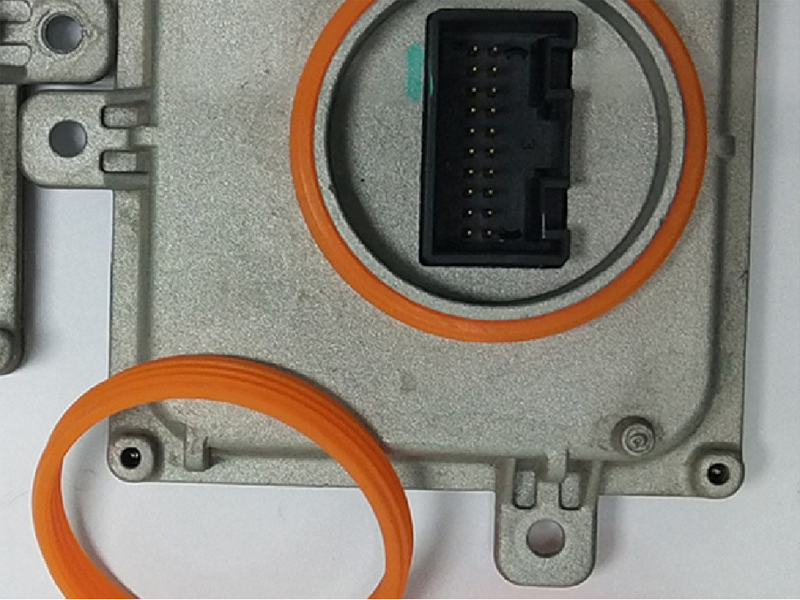

Enhanced O-Ring Systems

Overmolded O-Rings are resistant to extreme temperatures, chemicals, and pressures, ensuring long-lasting performance in critical automotive systems.

Connector Terminal Seals

Ensure secure, waterproof, and dustproof connections in electrical systems. Their flexibility and chemical resistance enhance durability and reliability.

Silicone Rubber Seals

Designed to minimize noise, absorb vibration, and prevent water ingress. These components improve ride comfort and protect sensitive electronics for automotive connecting terminals.

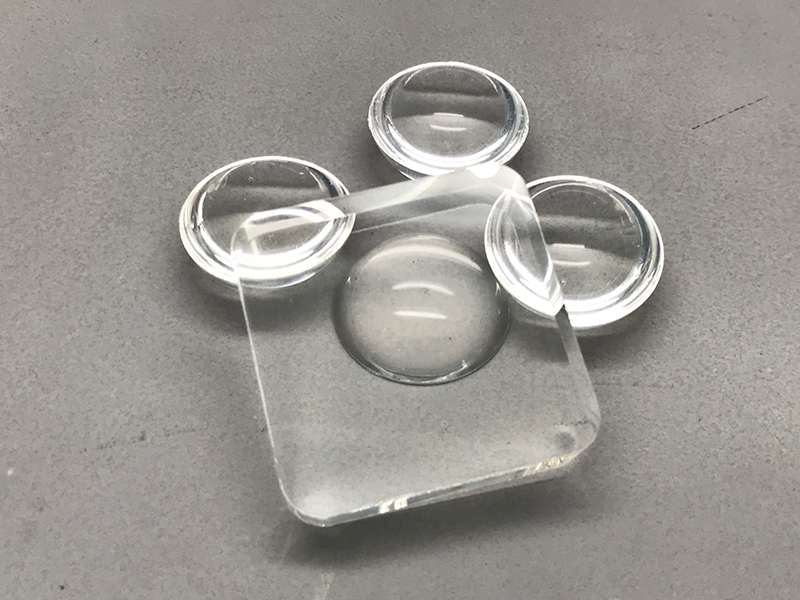

Automotive Optical Lenses

Featuring 95%-98% light transmission with exceptional thermal stability. With high-temperature resistance (up to 280°C), automotive silicone lenses perform reliably in extreme environments.

Frequently Asked Questions About Automotive Silicone Molding at Henry Precision

LSR is a versatile, high-performance material known for its flexibility, durability, and resistance to extreme temperatures and chemicals. In the automotive industry, LSR is used for sealing, insulation, vibration damping, and lightweighting to enhance vehicle efficiency and reliability.

LSR is commonly used for O-rings, gaskets, optical lenses, vibration damping components, connector seals, interior buttons, and antistatic coatings. It’s ideal for parts requiring precision, durability, and resistance to harsh conditions.

For electric vehicles, LSR provides superior insulation, thermal stability, and sealing for battery packs, connectors, and sensors. For autonomous vehicles, its optical clarity ensures high-performance lenses for cameras and sensors, while its durability enhances reliability.

Yes, Henry Precision specializes in custom solutions tailored to specific automotive needs. From design to production, we deliver silicone components with precise dimensions, optimal material properties, and tailored performance characteristics.

LSR’s lightweight nature helps reduce vehicle weight, improving fuel efficiency and lowering emissions. Its durability and longevity reduce the need for frequent replacements, minimizing waste.

We offer high-volume production with rapid turnaround times while maintaining precision and quality. Our advanced silicone for automotive applications enables complex designs and supports scalable production requirements.

Let’s build the future with innovation.

Please provide the following details to help us better understand your needs and get in touch with you as soon as possible.

You can send us 3D drawings in STL, STEP, IGES and 2D drawings in PDF. We will provide accurate quotations within 24 hours.

From concept to completion, we provide a one-stop silicone mold manufacturing service.