Medical Grade Liquid Silicone Rubber (LSR) Injection Molding | ISO 13485 Certified Factory

We specialize in medical-grade LSR injection molding with precision manufacturing in a Class 100K cleanroom.

Serving medical devices, automotive and new energy vehicles, 3C electronics, printing, and high-end consumer industries.

A seasoned team with decades of experience solving complex challenges in plastic and liquid silicone rubber injection molding.

Delivering optimized, tailor-made solutions for LSR molds and products to meet your unique requirements.

Receive an accurate quote within 24 hours, helping you make quick and informed decisions.

Expert-driven Design for Manufacturability reports with actionable recommendations for enhanced performance and efficiency.

Achieve up to 50% savings compared to European and American manufacturers without compromising quality.

A well-established production facility with expertise in plastic and liquid silicone rubber injection molding ensures exceptional results.

LSR INJECTION MOLDING - EVERYTHING YOU NEED TO KNOW

What Is LSR Injection Molding

Liquid Silicone Rubber (LSR) injection molding is a manufacturing process that uses liquid silicone to produce durable, flexible, and heat-resistant products.

LSR is biocompatible, resistant to extreme temperatures, and offers excellent chemical and electrical properties, making it ideal for diverse applications such as medical, automotive, and consumer industries.

LSR injection molding ensures precision, consistency, and efficiency in producing high-performance parts, reducing waste and costs.

At Henry Precision, we specialize in custom LSR injection molding, LSR overmolding, LSR 2-shot, LSR multi-shot processes, including silicone-wrapped PC, hardware, & glass. With over 60 advanced machines and a certified Class 100K cleanroom, we deliver high-quality, precision-molded LSR products to clients worldwide, helping our business partners thrive in their markets.

Applications of LSR Injection Molding

Since 2011, our expertise in liquid silicone injection molding and efficient delivery has helped thousands of clients succeed in various fields, including medical, automotive, electronics, and more.

Cooperation Process

Request a Quotation

Confirm the order

DFM Review

Production & Quality Assurance

Timely Delivery & After-Sales Support

Custom LSR Injection Molding Service - From Concept to Manufacturing

2 LSR Mold Options for Fast and Efficient Production

Regardless of your product’s lifecycle stage, we provide two tailored mold options to meet your needs:

- Our rapid prototyping molds significantly shorten development timelines, delivering molded parts in just days.

- For mass production, our on-demand manufacturing molds ensure fast part qualification and smooth scaling with advanced processes like scientific molding, GD&T-based CMM inspection, and comprehensive secondary operations for reliable performance.

| Sample Mould | Mass Production Mould | ||

| Mold | Simple mold | Mass production mold | |

| Mold Injection Life | Less than 2,000 molds | 300,000-1,000,000 molds (according to products) | |

| Mold Surface Treatment | According to product requirements | According to product requirements | |

| Material Selection | Die nut: S136H/P20 | Die kernel: S136 | |

| Mold grade (precision grade) (101 – 10) | According to the need of product requirements: 105 | According to need product requirements, 101/102/103/104 | |

| Quotation corresponding time | 24H | 24H | |

| Delivery time | 7-15days(1-2weeks) | 4-6weeks | |

| Mold storage and maintenance | Preservation: 24months | Storage: 36 months |

Suitable LSR Material for Injection Molding

Liquid Silicone Rubber (LSR) Materials (Shore Hardness: 0, 10, 15, 20, 30, 40, 50, 60, 70) | |

Types | characterization |

Food-Grade Silicone | Soft, skin-friendly, BPA-free, with color variations during high-temperature molding. |

Medical-Grade Silicone | Compliant with the big three of biocompatibility testing (cytotoxicity, sensitization, and irritation), eco-friendly, non-toxic, highly resilient, and exceptionally tough. |

Low-Temperature Silicone | Resistant to low temperatures, rapid vulcanization (no secondary vulcanization needed), eco-friendly, with excellent physical and mechanical properties, dimensionally stable, compliant with FDA standards, and resistant to fuels and oils to a certain degree. |

Quality Inspection

Upon quotation request, we offer tailored inspection standards and appearance guidelines.

Develop SOPs for production, sorting, and inspection of LSR parts.

Ensure LSR product quality with inspection reports.

Deliver scientific molding process and development report.

Use CMM and machine inspections.

Surface treatment

Based on product usage and requirements, we offer the following surface treatments:

- Silkscreening: Adding logos and patterns to silicone surfaces.

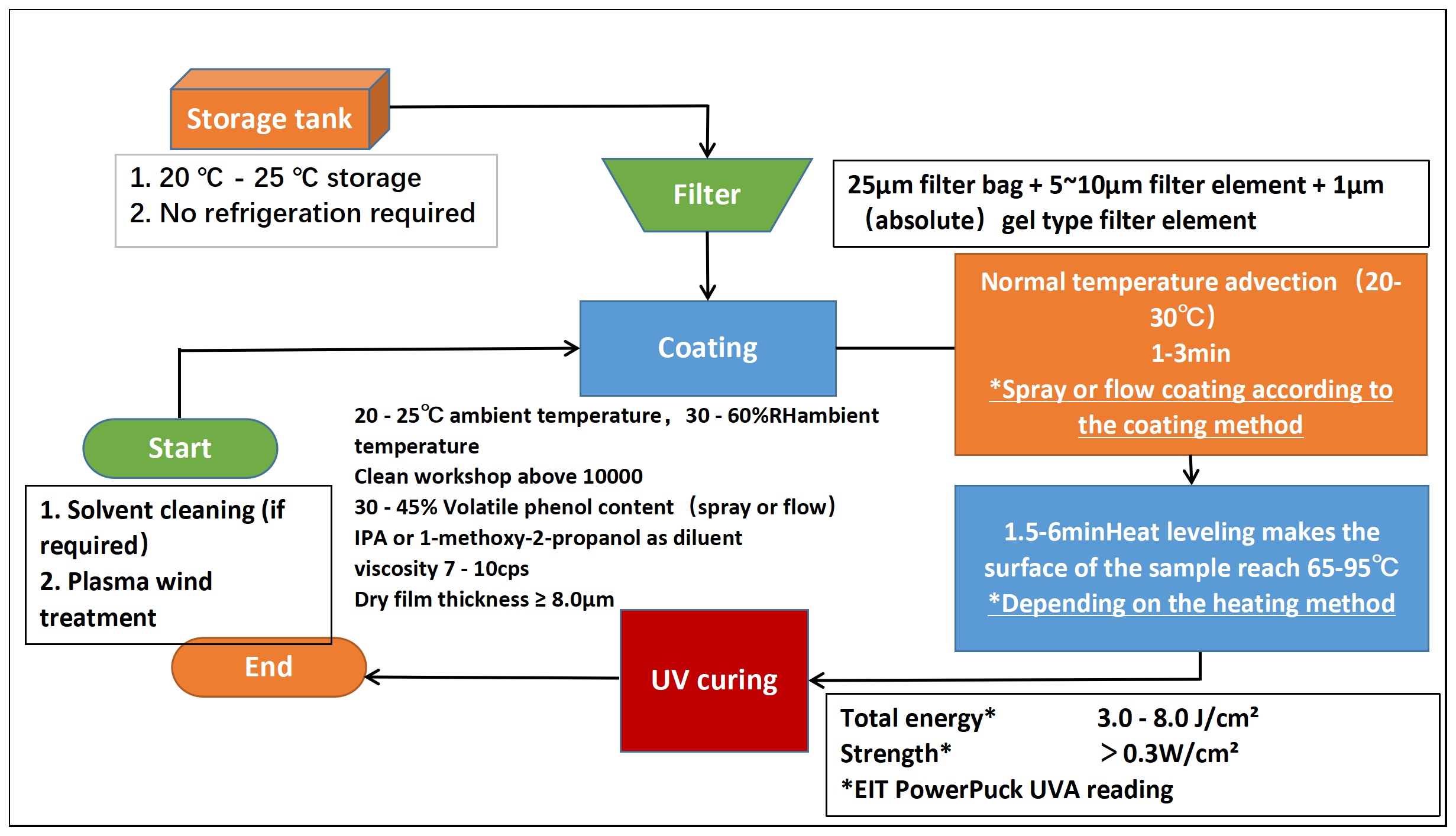

- UV coating: Enhancing product surface smoothness and tactile feel (suitable for medical supplies).

- Spraying feel oil: Increasing surface smoothness and tactile feel (suitable for daily use items).

Cases

This is an editable piece of text,This is an editable piece of text,This is an editable piece of text,

This is an editable piece of text,This is an editable piece of text,This is an editable piece of text,

This is an editable piece of text,This is an editable piece of text,This is an editable piece of text,

Enhance Your Project with Our Expert Services

Factory Tour

Partner with Henry-precision to Experience:

Premium LSR Injection Molding Excellence

- Advanced in-house tooling for precise LSR molded/overmolded components with small flying edges, no scrap and no extra finishing steps

- High quality plastic injection molded productswith high precision, low loss and high automation

- Streamlined manufacturing process

- Specialized cold runner systems for optimal material control

Advanced Manufacturing Capabilities

- State-of-the-art automated production facilities

- High-precision injection molding systems

- Integrated quality control processes

- Industry-leading 6Smanagement implementation

Expert Technical Support

- In-house mold design and engineeringexpertise

- 30+specialized technical professionals

- Customized R&D solutionsin medical industry, high-tech field, and more

Comprehensive project support from concept to production

Let’s build the future with innovation.

Please provide the following details to help us better understand your needs and get in touch with you as soon as possible.

You can send us 3D drawings in STL, STEP, & IGES, and 2D drawings in PDF. We will provide accurate quotations within 24 hours.

From concept to completion, we provide one-stop silicone mold manufacturing service.