Liquid Silicone Injection Molding (LSR) and foaming technology offer many benefits. These technologies are widely used in various industries such as automotive, electronics, and home products. They provide strong performance, flexibility, and eco-friendly advantages. This article will discuss the benefits of liquid silicone injection molding and its applications in different fields.

1. How Liquid Silicone Injection Molding Works

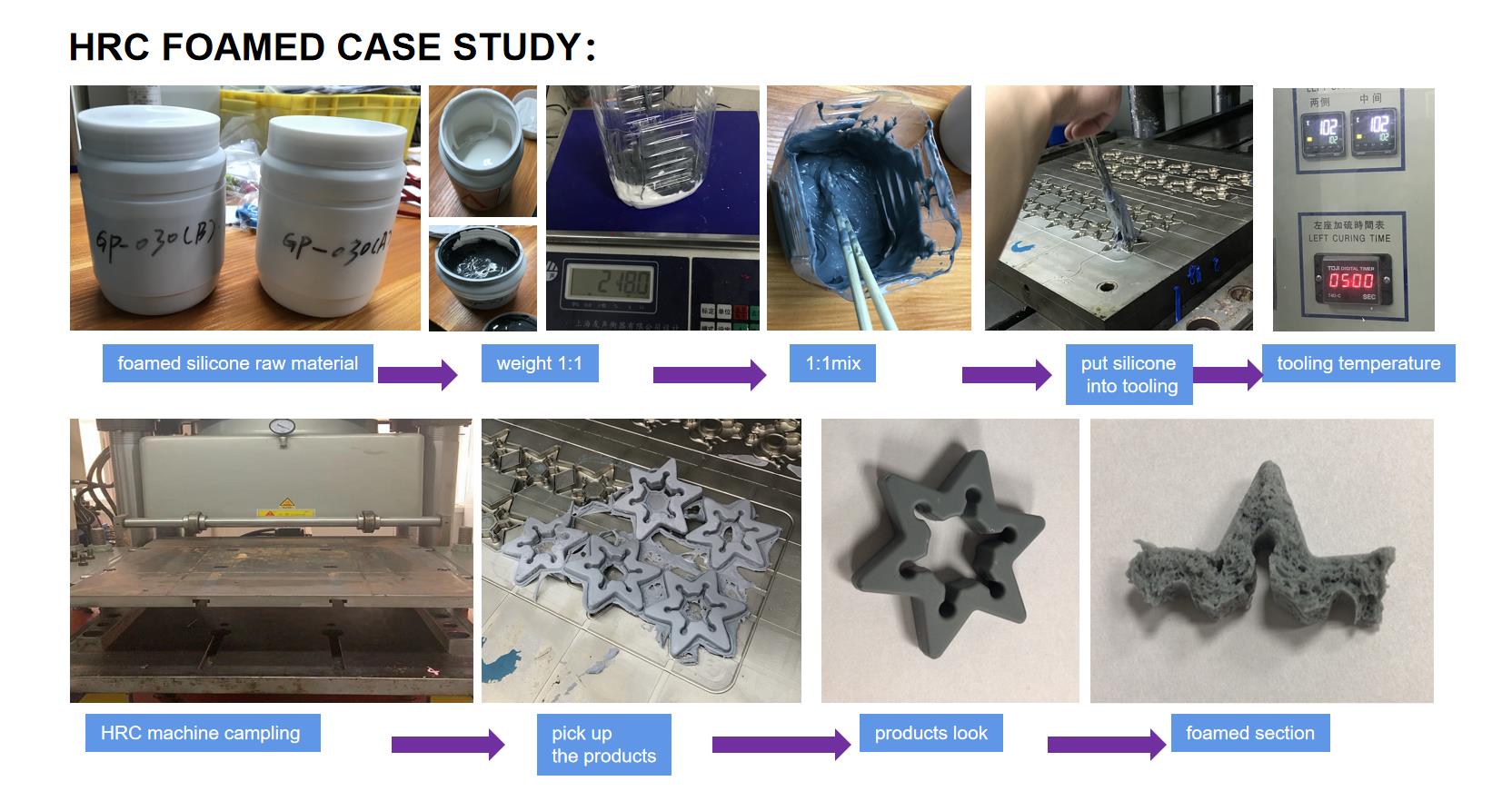

To ensure high-quality products, follow these steps when using liquid silicone injection molding:

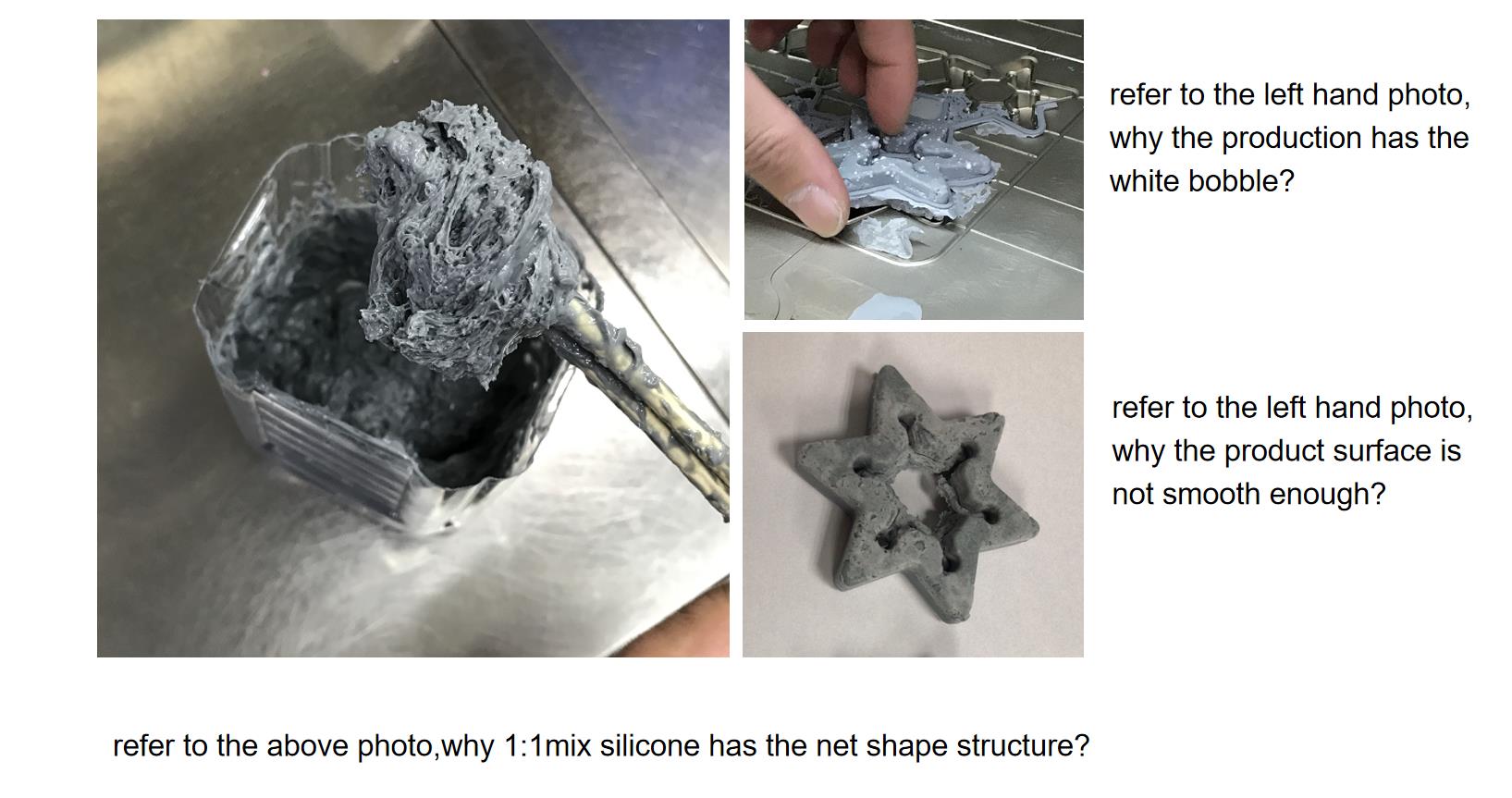

- Stir the Material: Before use, make sure to stir the silicone material well to avoid uneven mixing.

- Mix in Proportion: Mix the A and B components in a 1:1 ratio and stir for 2-3 minutes to ensure uniformity.

- Vacuum Treatment: After stirring, treat the mixture under vacuum and use it as soon as possible to prevent condensation from affecting production.

Following these simple steps will help ensure consistency and quality in the final product.

2. Applications of Liquid Silicone Injection Molding and Foaming Technology

Liquid silicone foaming is a very useful material, and it has many applications across different fields:

- Car and Aircraft Seat Cushions: This material is ideal for making flexible seat cushions and pillows with excellent resilience and durability.

- Home Products: It is also used for making sofa cushions, mattresses, and other home products to offer a comfortable experience.

- Sealing for Electronics: Liquid silicone foaming is great for sealing electronic products, offering good waterproof properties without adding extra pressure on the electronics.

3. Advantages of Liquid Silicone Foaming

Liquid silicone foaming has several key advantages:

- Heat and Cold Resistance: It maintains stable performance in both high and low temperatures.

- Electrical Insulation: It is a great insulating material to protect electronic devices.

- Flame Resistance: It can be used in fire protection applications due to its flame-retardant properties.

- Eco-Friendly: Liquid silicone foaming is an environmentally friendly material, making it a great choice for many sustainable industries.

4. Specific Applications of Liquid Silicone Foaming

- Filling Material: Liquid silicone foaming is often used as a filling for products like toys, cushions, and pillows. Its great elasticity and flame-resistant qualities make it ideal for consumer products.

- Foam Board: It can replace traditional PU foam boards, offering better stability and durability.

- Sealing Material: Liquid silicone foaming is also used as a sealing material in electronics. It provides excellent waterproof protection without adding extra weight or pressure on the device.

5. Looking Ahead

The use of liquid silicone injection molding and foaming technology is transforming many industries. These technologies offer reliable and eco-friendly solutions. As technology advances, the demand for liquid silicone products is expected to grow.

Contact Us

If you want to learn how liquid silicone injection molding or foaming technology can help your product, feel free to contact Henry Precision. We will provide you with professional support and solutions.